Automatic control system d-Control

Automatic control system d-Control

Automatic control system d-Control

d-Control is the open architecture DeltaV solution for bioreactors. It uses the Emerson DeltaV software suit.

The control system combines the best of DeltaV automation with Applitech bioprocessing know-how into one platform.

The process control experiences and data management can be easy to transfer from Lab to Pilot and Production.

Seamless technology transfer and scalable data transfer result in optimal bioprocesses with shorter development lead time and lower development costs.

d-Control is the open architecture DeltaV solution for bioreactors. It uses the Emerson DeltaV software suit.

The control system combines the best of DeltaV

automation with Applitech bioprocessing know-how into one platform.

The process control experiences and

data management can be easy to transfer from Lab to Pilot and Production.

Seamless technology transfer and scalable data transfer result in optimal bioprocesses with shorter development lead time and lower development costs.

Benefits

Provides modern technologies and software solutions

d-control system provides you with a real-time database. Display, trend, alarm and even can be used in control strategies.

Offer greater flexibility and scalability

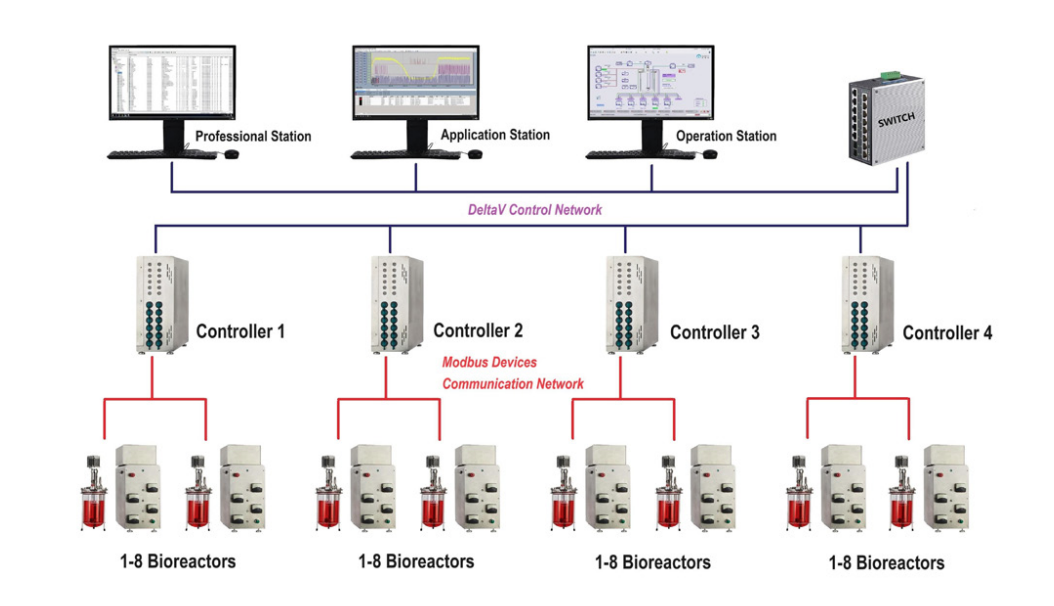

Connections from single to 32 bioreactors. Can connect with 3rd party data for advanced control strategies. Customized functions can meet any complex control requirements. The data in control system can be delivered to upper-level system (MES, LIMS, ERP etc.).

Improved user experience with advanced automation tools and easy to use

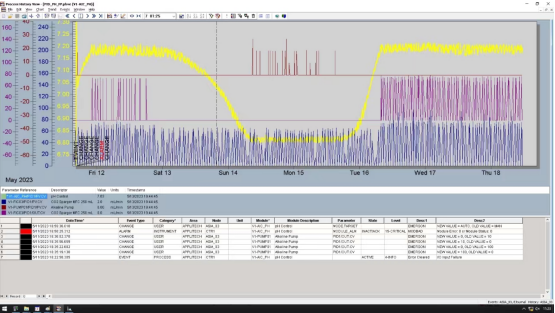

Operation system gives users direct access to all kinds of operating information — including current process values, operating displays, and alarms with proper alarm priority and timestamp

Reduced time-to-market and development costs

Easy transfer from

Laboratory to Pilot and Production.

Architecture

System architecture, hardware, software, and interfaces blend to create a setting where engineers and operators smoothly grasp situations and use tools to devise solutions. Connect via industry standard OPC that provide connections to other systems.

Features

Open-architecture

Use open communication protocols scalable system architecture.

DeltaV software with customer-made functions

Customize control strategies according to different needs of customers.

Alarm

Alarms are provided in order of importance to the operator, based on priority, acknowledgement status, active status, and area of responsibility diagnostics.

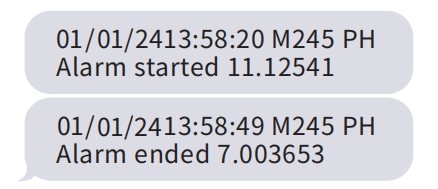

SMS Alarm

Send key alarm information that occurs during the production process to designated personnel. It is convenient for production personnel to deal with it in a timely manner.

Process History View

Status information and alarm and event data collected by the DeltaV system is embedded in the trend to provide a more accurate and thorough historical picture.

Reporter

The MS-Excel based reporting and analysis tool, provides an easy way to get historical data into an Excel spreadsheet.

Advanced automation tools for the

best user experience

- Bioreactor overview

- Sensor/Actuator calibration

- Dose Monitors

- Total Gas Flow

- Weight Control

- 3-point cascade

- Perfusion

- Cultivation mode

Applications

-Microbial and Cell cultivation

-Feed, Perfusion and Continuous

cultivation

-Single-use Bioreactor processes

-Stainless steel Bioreactor for pilot and commercial production bioreactor process