Stainless Steel Bioreactor

Stainless Steel Bioreactor

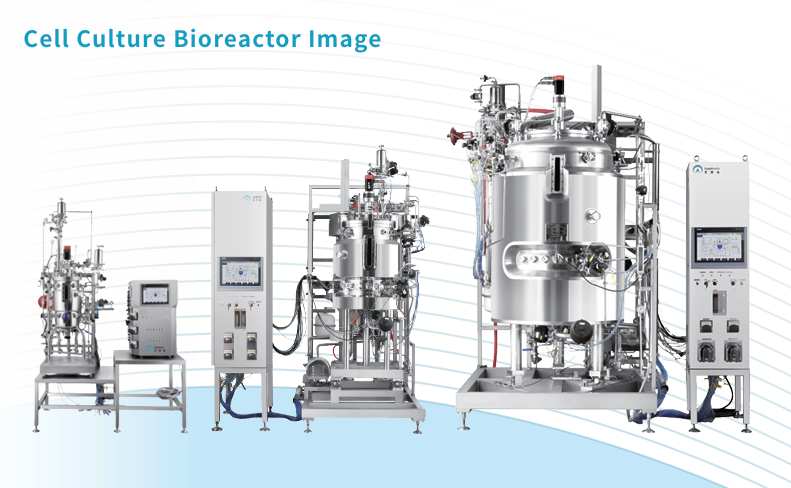

AbioPilot Stainless Steel Bioreactors

• Constructed with 316L stainless steel, with an external surface finish available in brushed or mirror-polished options for easy cleaning.

• All parts in contact with culture media are electropolished (Ra < 0.4µm) to ensure efficient CIP cleaning.

• Open frame structure facilitates easy maintenance and operation.Modular design easily adapts to evolving process requirements.

• GMP-compliant design simplifies validation processes.

• Compact footprint saves space.

With nearly 20 years of experience in the biopharmceutical industry and a dedication to craft high-end bioreactors, backed by a highly skilled R&D team of over 150 professionals, Applitech proudly presents the AbioPilot Stainless Steel Bioreactor.

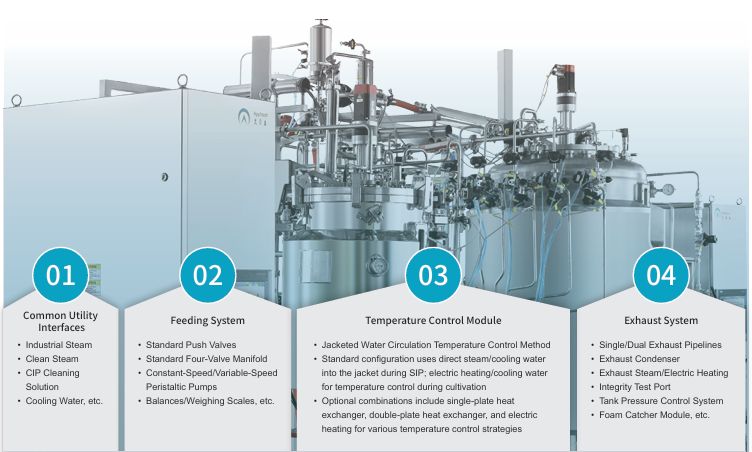

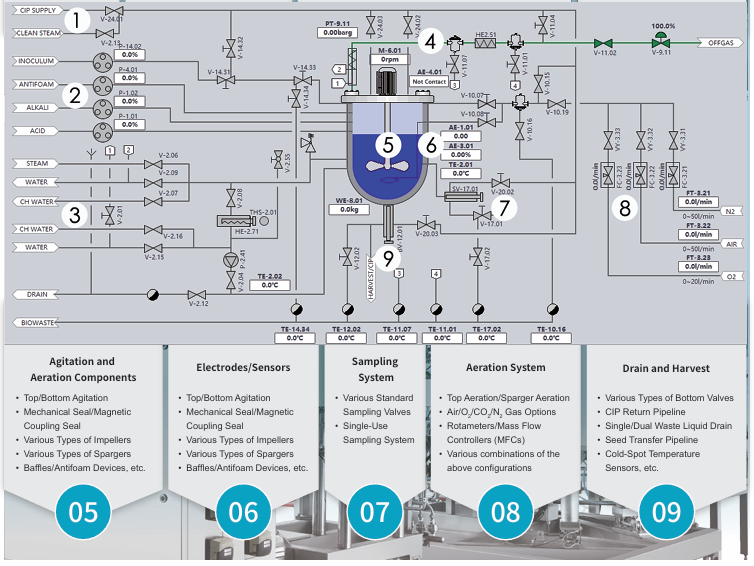

Adopting a modular design philosophy, Applitech’s stainless steel bioreactors cater to diverse user requirements. For pilot-scale operations, we offer standard volumes for cell culture and microbial fermentation tanks, simplifying the design process for pilot and small-scale production. For larger scales or non-standard volumes, we support fully customizable designs, with capacities up to 20,000 liters.

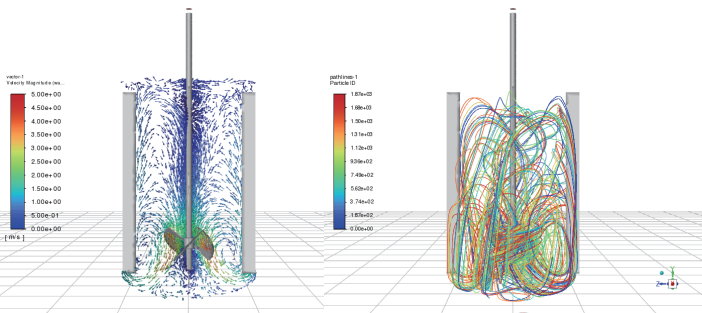

Applitech stainless steel bioreactors support cleaning options including CIP and SIP. During the design phase, we employ CFD fluid dynamics simulation models and 3D modeling. All designs adhere strictly to ASME BPE guidelines and meet GMP and GAMP validation requirements, offering seamless scalability from laboratory to production.

Features

• Constructed with 316L stainless steel, with an external surface finish available in brushed or mirror-polished options for easy cleaning.

• All parts in contact with culture media are electropolished (Ra < 0.4µm) to ensure efficient CIP cleaning.

• Open frame structure facilitates easy maintenance and operation.Modular design easily adapts to evolving process requirements.

• GMP-compliant design simplifies validation processes.

• Compact footprint saves space.

Applications

• Designed to meet GMP standards, equipped with audit tracking functionality.

• Cultivation of mammalian cells, plant cells, insect cells, microorganisms, and fungi.

• Ideal for vaccine, antibody, and cell/gene therapy production and scale-up.

• Supports batch, fed-batch, perfusion, and continuous culture processes.

• Applicable for pilot-scale and large-scale production.

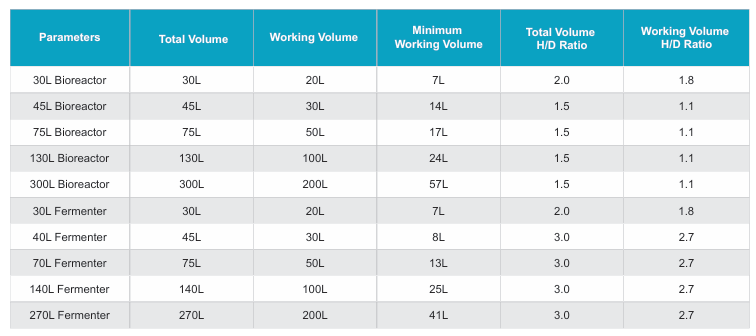

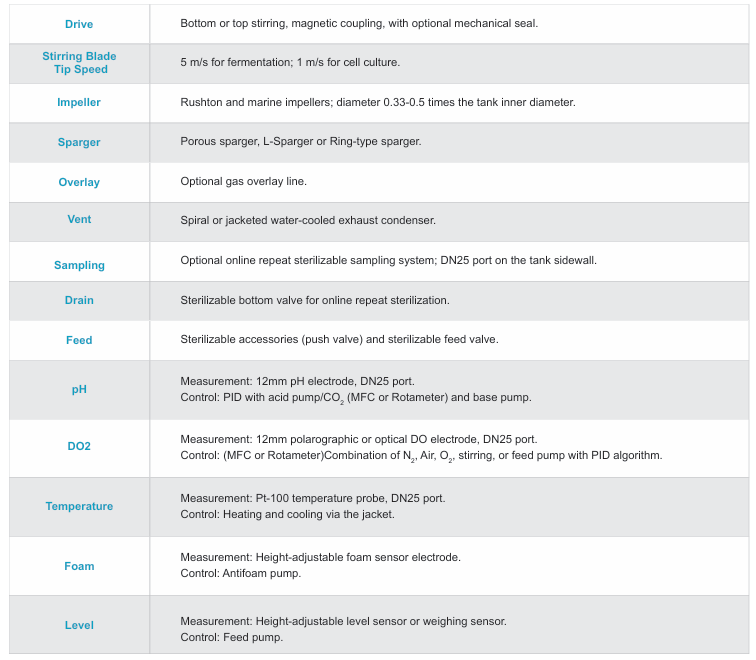

AbioPilot Technical Specifications