Parallel Bioreactor System

Parallel Bioreactor System

AbioBundle Multimini Series Parallel Bioreactor System

- Small-scale parallel bioreactor system equipped with an embedded controller and industrial PC.

- Parallel control allowing four vessels to operate either independently or simultaneously.

- One of the smallest-volume (50 mL) stirred-glass parallel bioreactor systems available on the market, enabling low working volumes and reducing overall experimental costs.

- Peltier-based temperature control, a water-free system that reduces laboratory water consumption and eliminates cooling-water residue.

- Highly integrated and compact design, with a total footprint of less than 0.5 m² for all four vessels.

- Unique feeding design enabling rapid switching between single-use feed bottles and centrifuge tubes to accelerate feed-type changes.

- Applitech Aiopt proprietary algorithm ensures precise control of critical process parameters.

- Each vessel supports up to three variable-speed pumps, each equipped with an independent Prime button for easy tubing priming or emptying.

- Compatible with intelligent pH/DO sensors, balances, external pumps, and other peripherals.

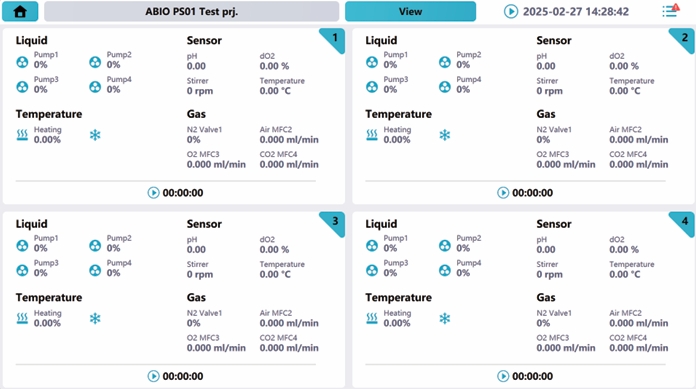

- Supports external displays or WebUI operation, providing a simple and user-friendly interface.

Features

- Small-scale parallel bioreactor system equipped with an embedded controller and industrial PC.

- Parallel control allowing four vessels to operate either independently or simultaneously.

- One of the smallest-volume (50 mL) stirred-glass parallel bioreactor systems available on the market, enabling low working volumes and reducing overall experimental costs.

- Peltier-based temperature control, a water-free system that reduces laboratory water consumption and eliminates cooling-water residue.

- Highly integrated and compact design, with a total footprint of less than 0.5 m² for all four vessels.

- Unique feeding design enabling rapid switching between single-use feed bottles and centrifuge tubes to accelerate feed-type changes.

- Applitech Aiopt proprietary algorithm ensures precise control of critical process parameters.

- Each vessel supports up to three variable-speed pumps, each equipped with an independent Prime button for easy tubing priming or emptying.

- Compatible with intelligent pH/DO sensors, balances, external pumps, and other peripherals.

- Supports external displays or WebUI operation, providing a simple and user-friendly interface.

Applications

• Cultivation of mammalian cells, stem cells, microorganisms, fungi, plant cells, and insect cells.

• Cell line screening, process optimization, media development, and toxicity studies.

• Supports high-density, aerobic and anaerobic fermentation, as well as protein expression studies.

• Process development in vaccines, antibodies, and cell/gene therapy.

• Compatible with batch, fed-batch, perfusion, and continuous culture modes.

• The Multimini bioreactor is an upgraded design based on the m-Control, capable of controlling four glass vessels simultaneously—accelerating condition screening and process verification.

• Modular design allows for customized development tailored to specific process requirements.

Contact Us