Mixing Systems

Mixing Systems

AbioMixer Benchtop Mixing System

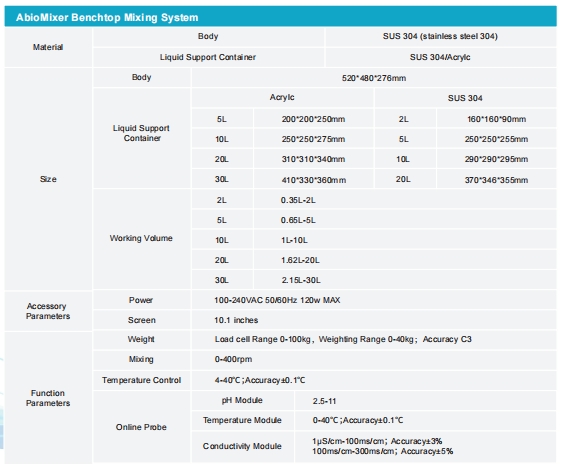

The AbioMixer Benchtop Mixing System, independently developed by Applitech, supports mixing needs for solutions with volumes ranging from 0.35L to 30L.While ensuring data integrity throughout the entire drug development and production process, it strengthens the control of key parameters by real-time monitoring within the system, providing both data and theoretical support for precise control of important parameters in production and process development.

AbioMixer Benchtop Mixing System

The AbioMixer Benchtop Mixing System, independently developed by Applitech, supports mixing needs for solutions with volumes ranging from 0.35L to 30L.

While ensuring data integrity throughout the entire drug development and production process, it strengthens the control of key parameters by real-time monitoring within the system, providing both data and theoretical support for precise control of important parameters in production and process development.

The AbioMixer Benchtop Mixing System is used with pre-sterilized single-use magnetic stirring bags, ensuring complete isolation between the system and the external environment. Additionally, through the transparent bag and probe modules on the device, the status of the liquid and various parameters can be monitored at any time, integrating control, observation, and data storage in one system.

Features

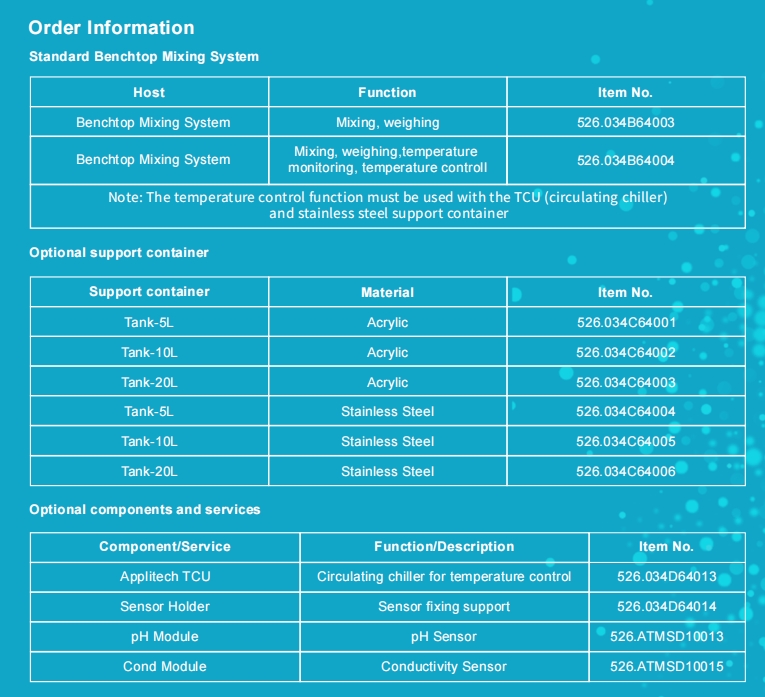

- Modular design allows for optional expansion of equipment functions to meet different process requirements.

- By pairing with Haimore Single-Use Bags, the equipment eliminates the need for cleaning or sterilization processes, streamlining the mixing procedure for greater efficiency.

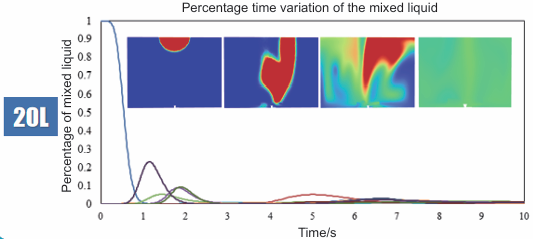

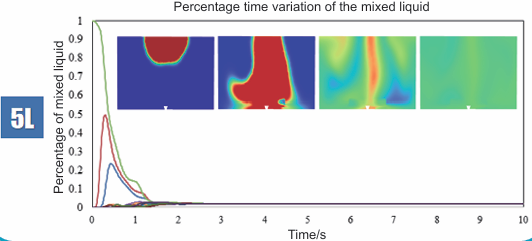

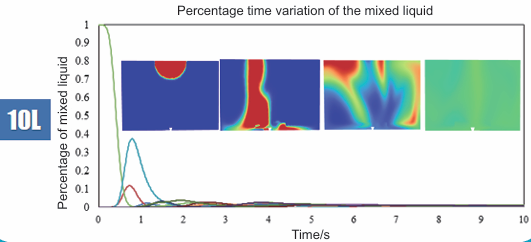

- The entire series has undergone fluid dynamics validation, with scientifically optimized stirring solutions achieving a minimum mixing time of 3 seconds.

- Interchangeable liquid container design allows a single system to be compatible with different size container to meet different needs.

- Support user permission matrix, audit trail, data management, comply with GMP and 21CFR Part 11 requirements.

Fluid Dynamics Simulation Results

Application Scenarios

Commercial

For small-volume mixing requirements of buffer solutions and intermediate products in commer cial production processes: Extends the scale of conventional mixing systems to 0.35L, address ing the data gap in the handling of small-volume solutions in conventional processes, while meeting GMP requirements for data integrity and audit trail.

Lab-scale

For the preparation of culture media, buffer solutions, and product mixing during the lab-scale research phase: Enhances data integrity during the project develop ment cycle, reduces operator interference in condition-controlled experiments, and ensures consistency in mixing effects across different experimental batches.

Pilot-scale

During the pilot scale-up phase of process development, where mixing process parameters are critical: The process parameters provided by the benchtop mixing system can serve as a reference for subsequent scale-up parameters, ensuring that every stirring coefficient and weight parameter is supported by data, providing theoretical support for process scaling.

Optional Features

Temperature Detection Module

Detects the internal temperature of the system in real-time through a temperature sensing component. It can be combined with a temperature control jacket and TCU to control the temperature of the liquid in the system.

Temperature Control Module

Use a temperature control jacket and TCU to precisely control the temperature of the liquid in the system.

pH Module

Real-time monitoring of the pH inside the system using a pH sensor.

Conductivity Module

Real-time monitoring of the conductivity inside the system using a conductivi ty sensor.