Wave Bioreactor

Wave Bioreactor

AbioWave Rocking Bioreactor

• PLC control system that ensures stable performance

• Gamma-irradiated single-use culture bags are pre-steril ized, reducing contamination risks and simplifying validation processes.

• Alllows for flexible tray replacement, accommodating various culture volumes to meet different requirements.

• Highly customizable, offering maximum flexibility to tailor configurations to specific needs.

• Features a user-friendly interface with intuitive operation, supporting OPC protocols and compliance with FDA 21 CFR Part 11.

• Optional AbioPIMS software enables real-time monitoring and advanced data management across multiple units.

AbioWave Rocking Bioreactor

The AbioWave Rocking Bioreactor utilizes advanced wave motion technology to provide an efficient, controllable, and scalable environment for cell culture processes. This innovative design replicates the fluid mixing effects of traditional stirred tank reactors while eliminating the mechanical shear and bubble introduction issues associated with conventional agitators. AbioWave employs disposable AbioBag culture bags as the cultivation vessel, eliminating the need for cleaning and sterilization, thus reducing product development time and costs. It supports single-use culture bags with total volumes of 2L,10L,20L,22L,and 50L, covering working volumes ranging from 0.3L to 25L, making it suitable for research, pilot-scale, production, and seed expansion applications.APPLICATIONS

The AbioWave Rocking Bioreactor is versatile and supports a

wide range of cell culture applications, including mammalian

cells, human stem cells, insect cells, and plant cells.

• Batch Culture

• Fed-Batch Culture

• Perfusion Culture

• Adherent Cell Culture

Features

- PLC control system that ensures stable performance.

- Use of pre-irradiated sterilized culture bags to reduce risk of contamination and fixed inputs for CIP/SIP in production.

- Alllows for flexible tray replacement, accommodating various culture volumes to meet different requirements.

- Highly customizable, offering maximum flexibility to tailor configurations to specific needs.

- Optional 1-to-2 configuration, allowing two cultures to be processed simultaneously.

- Features a user-friendly interface with intuitive operation, supporting OPC protocols and compliance with FDA 21 CFR Part 11.

- Optional AbioPIMS software enables real-time monitoring and advanced data management across multiple units.

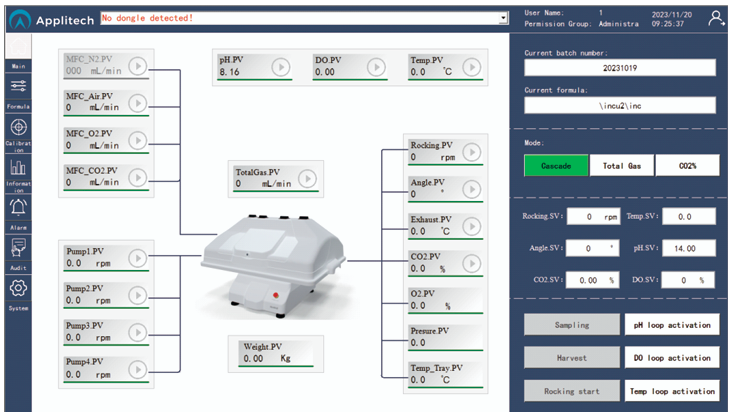

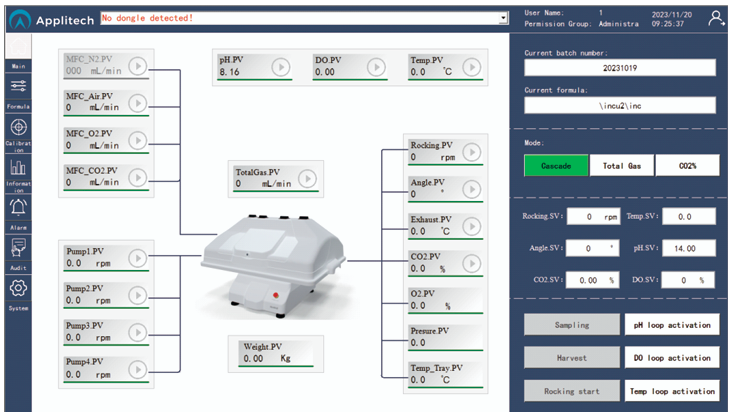

AbioControl IDS.W Controller

- Using Siemens PLC S7-1500, high-performance PLC, safe and reliable.

- Using Net SCADA development interface, with OPC, hierarchical permissions, Audit trail function, data compliance with 21 CFR Part 11.

- 13.5 in. operating interface, touch screen, with a stylus for easy operation.

- Integrated with precise PID algorithm control for temperature, pH, DO, weight, etc. User-defined cascade function, rich process mode options, and out-range alarm function.

- With pH/DO, total ventilation, CO2 concentration mode three control modes for users to choose, to meet the needs of different culture process.

- Built-in SCADA software for real-time data recording and storage, which can realize advanced data operation such as data curve view, export and comparison.

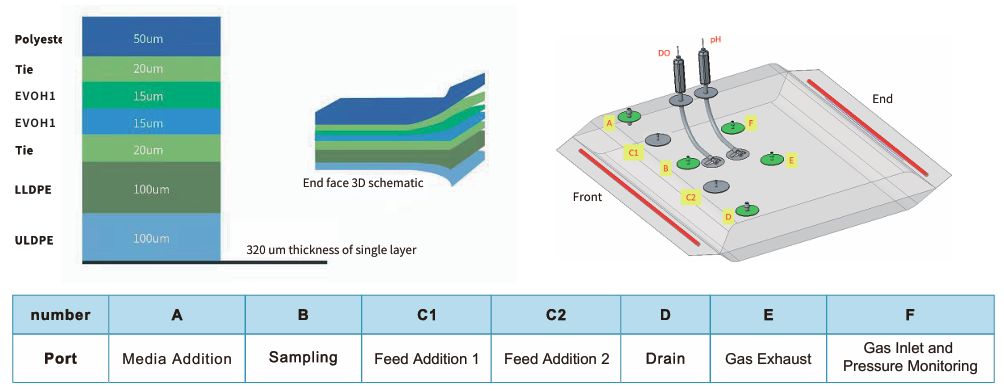

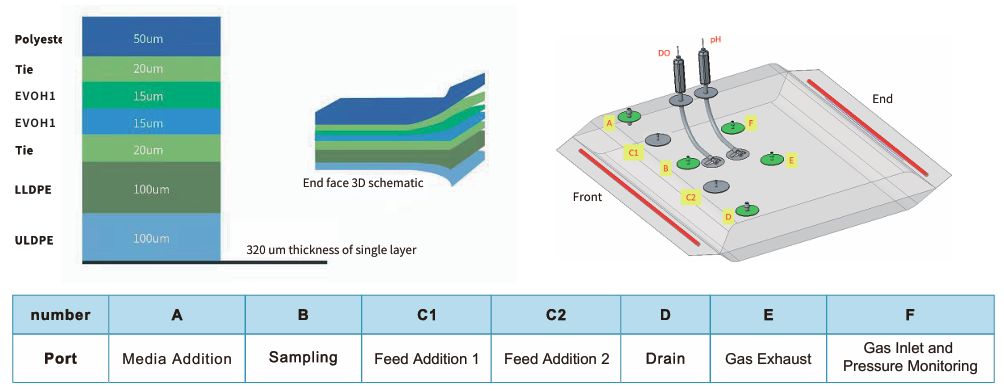

AbioBag Culture Bag

AbioBag culture bags are constructed using a 7-layer composite co-extruded film, free from animal-derived components, with a total thickness of 320 μm, providing excellent strength and resistance to mechanical stress.The innermost layer is made of ultra-low-density polyethylene (ULDPE), which directly contacts the sample, providing

superior biocompatibility and the necessary flexibility for various applications.

These bags are sterile, pyrogen-free, and highly gas-tight, meeting international biosafety standards such as USP Class VI

and ISO 10993 with complete material certification and can be extensively customized to meet specific customer

requirements.

Contact Us