Single-use Bioreacor

Single-use Bioreacor

AbioSUS Single-Use Bioreactor

The AbioSUS Single-Use Bioreactor is a comprehensive system comprising a stainless-steel bag holder (integrated with a TCU for temperature control), the AbioControl IDS.S controller, and the AbioBag culture bag.

Designed to replicate the conditions of traditional stirred-tank bioreactors, the AbioSUS ensures that process condi tions are comparable, enabling seamless transition between research, development, and production platforms.

Available in standard sizes of 50L, 200L, 500L, 1000L, and 2000L, with customization options, the AbioSUS supports a wide range of upstream cell culture applications for antibodies, vaccines, and cell/gene therapies.

The AbioSUS Single-Use Bioreactor is a comprehensive system comprising a stainless-steel bag holder (integrated with a TCU for temperature control), the AbioControl IDS.S controller, and the AbioBag culture bag.

Designed to replicate the conditions of traditional stirred-tank bioreactors, the AbioSUS ensures that process condi tions are comparable, enabling seamless transition between research, development, and production platforms.

Available in standard sizes of 50L, 200L, 500L, 1000L, and 2000L, with customization options, the AbioSUS supports a wide range of upstream cell culture applications for antibodies, vaccines, and cell/gene therapies.

Stainless-Steel Bag Holder

Dual-Jacket Design:Both the bag holder and door feature a dual-jacketed structure connected to an integrated TCU, facilitating temperature control via water circulation within the jacket.

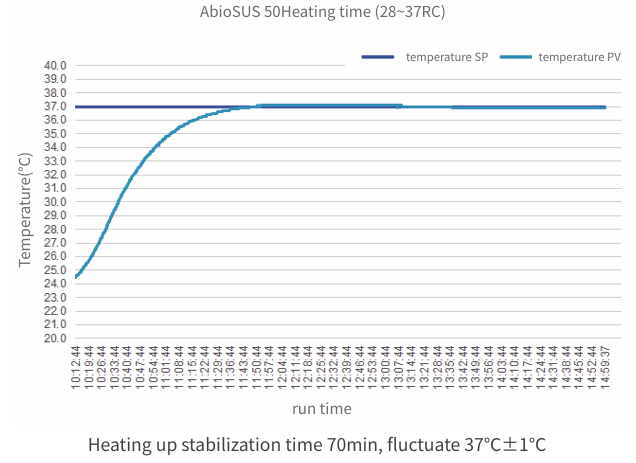

Temperature Range: 8°C - 40°C ±0.1°C (requires cooling water ≤8°C).

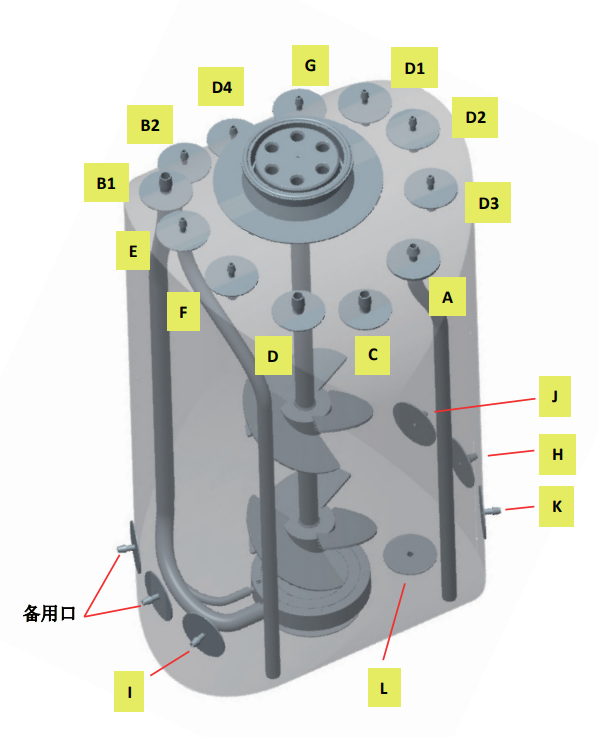

AbioBag Culture Bag:

The culture bag is mounted on a fixed frame and, once connected to the AbioSUS, forms a complete bioreactor system.

Constructed from 7-layer coextruded film.

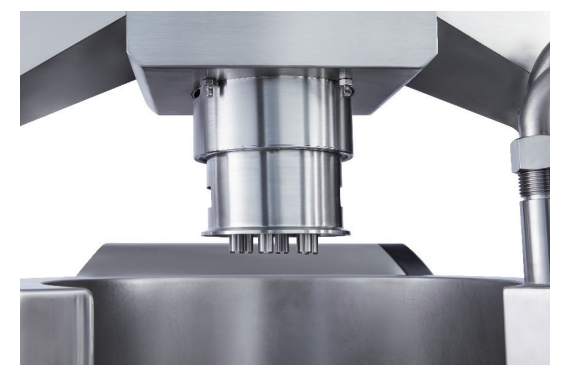

Includes a dual-blade Marine impeller and dual bottom sparger ports.

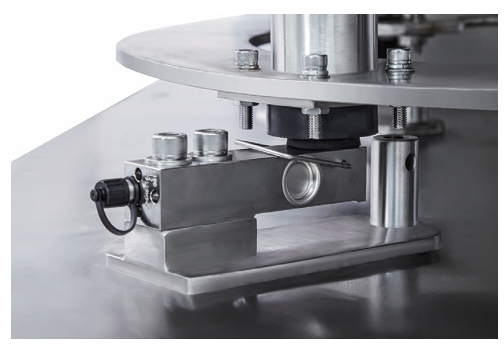

Weighing Sensor Support Bracket:

During transport or long periods of non-use, the bracket absorbs load to prevent sensor damage.

During operation, the bracket is removed, allowing the C6-grade weighing system to monitor the culture weight directly.

Fixed Support Frame:

Secures the AbioBag culture bag, accommodates various filters, and organizes cables and tubing for enhanced durability and appearance.

Exhaust gas electric heating blanket.

Servo-driven stirring motor.

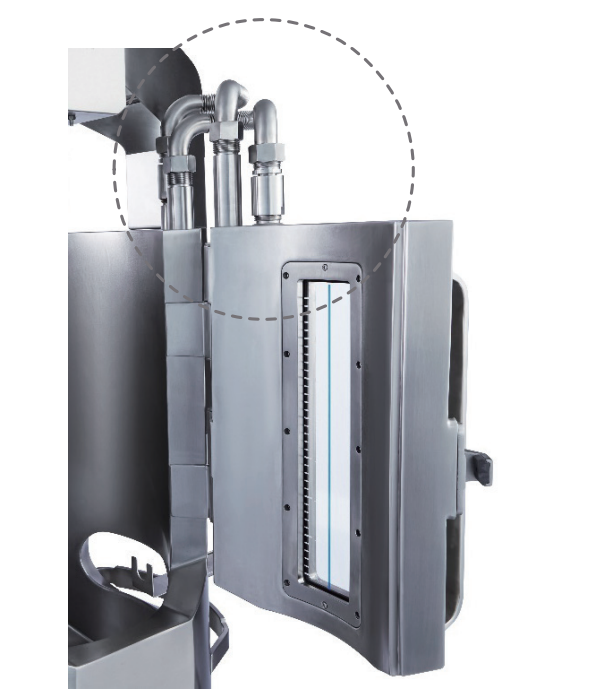

Door with Observation Window:

Large single-opening door simplifies bag replacement and features a transparent, graduated window for easy observation of the bag’s contents.

Dual-jacketed designed door for better temperature control.

Sensor Operation Area:

Mirrors the sensor interface arrangement of traditional stainless-steel bioreactors for familiar operation, ensuring full immersion of sensors in the culture medium while minimizing damage risk from proximity to the impeller.

Supports traditional and single-usepH/DO sensors, with options fordual pH and dual DO configurations.

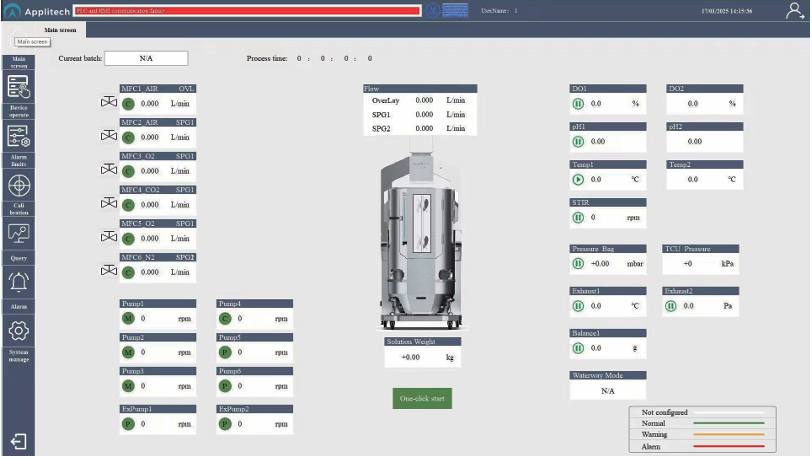

AbioControl IDS.S controller

• The controller's modular design offers flexible configurations suitable for a wide range of applications, supporting single-use bioreactors from 50L to 2000L.• Includes five levels of operational access (View, Operator, Engineer, Supervisor, Administrator). Permissions manage ment ensures controlled production processes, with audit trail capabilities logging all operations.

• Equipped with an anti-mistouch and screen-lock function to secure the production process.

• Supports multiple control loops, including temperature, agita tion, pH, and DO. All process parameters are displayed, and process control strategies can be adjusted as needed.

• Flexible Cascade Control Loops allows switching based on control requirements to maintain parameter stability, ensuring experimental reproducibility and process consistency.

• Supports integration with third-party devices such as variable-speed pumps, mass flow controllers (MFCs), balances, and off-gas analyzers via 4-20mA or Modbus. It facilitates interaction with multiple control software systems and seamless data transfer.

• Customizable configurations to meet client-specific require ments.

• Equipped with a 24V DC UPS power supply to ensure the stability of the control and monitoring system and maintain continuous data recording.

• Enables quick switching of bottom aeration pathways via software.

• Designed to minimize footprint, saving valuable space.

Operation interface

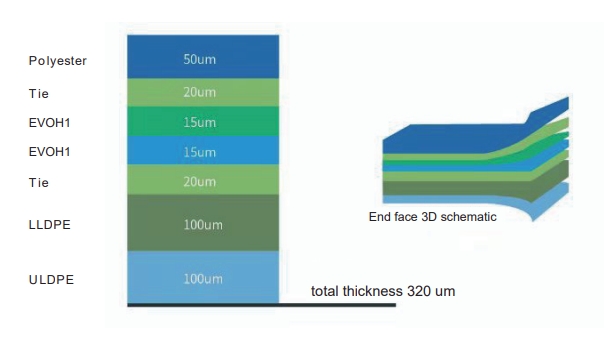

AbioBag culture bag

AbioBag culture bags are constructed using a 7-layer composite co-ex truded film, free from animal-derived components, with a total thickness of 320 μm, providing excellent strength and resistance to mechanical stress.

The innermost layer is made of ultra-low-density polyethylene (ULDPE), which directly contacts the sample, providing superior biocompatibility and the necessary flexibility for various applications.

These bags are sterile, pyrogen-free, and highly gas-tight, meeting international biosafety standards such as USP Class VI and ISO 10993 with complete material certification and can be extensively customized to meet specific customer requirements.

AbioSUS Single-Use Bioreactor Features

Top-mounted motor drive facilitates quick and conve nient assembly and disassembly.

Large single-door design allows for easy loading and unloading of the culture bag.

Double-Layered Jacket for the entire bag holder (including the door). Water circulation system for heating or cooling, with synchronized temperature control on the door to enhance overall temperature uniformity.

C6-Grade load sensors provides highly accurate weight measurements.

Supports both traditional and single-use pH/DO sensors, with the ability to simultaneously use dual pH and dual DO sensors.

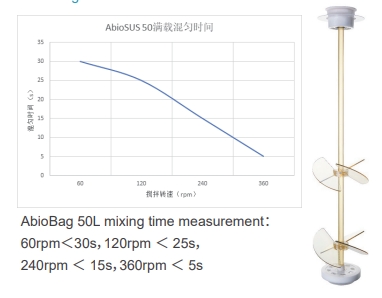

Dual impeller design ensures consistent and efficient mixing across different volumes.

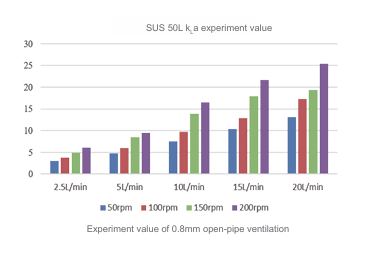

Features a 0.8 mm macro-bubble and a 150 µm micro-bubble aeration system, allowing for online switching between multiple aeration strategies. Improves KLa, enhances pH control, and reduces foam formation. Aeration port types and specifications are customizable.

The bag holder integrates the TCU Temperature Control System eliminating the need for external heating or cooling devices (Includes TEC cooling to prevent overheating). The TCU is controlled through the IDS.S controller.

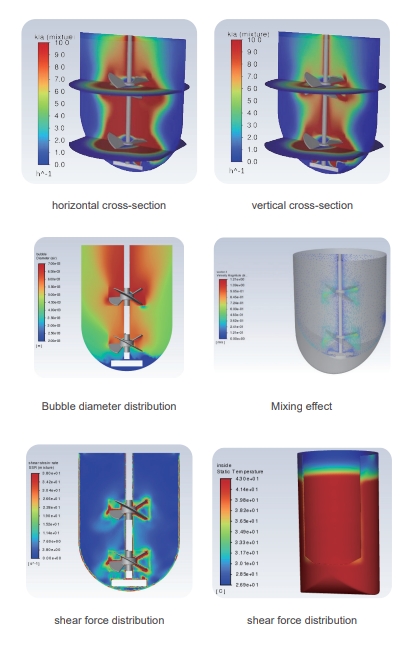

Performance verification of the single-use bioreactor was conducted using CFD (Computational Fluid Dynamics) analysis. The results demonstrated excellent oxygen transfer capabilities and effective mixing uniformity. The bioreactor provides low shear force and consistent heating, meeting the condition requirements for optimal cell culture growth.