Company news

Company news

Radial chromatography technology helps Tianjin kelaiying purification efficiency increased by 3 times

What is radial chromatography?

In traditional axial flow chromatography, the fluid flows from one end to the other end of the column, usually from the upper end to the lower end of the column, and the liquid flow direction flows downward along the central axis gravity direction.

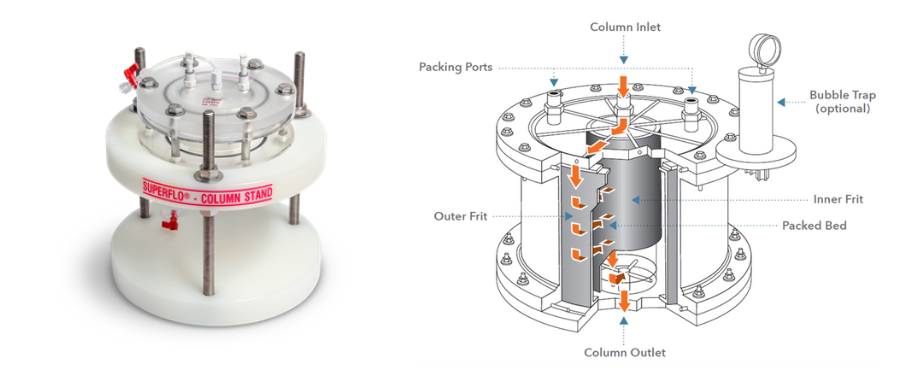

Radial flow chromatography is different from traditional axial flow chromatography in that the mobile phase of radial flow chromatography carries the sample along radial direction. The radial column is designed to be sleeve-like, i.e., the packing shape is not the traditional column shape, but similar to the donut shape. The column contains inner and outer surfaces, and the middle channel is loaded with packing.

Generally, the mobile phase in the radial layer system enters from the top of the column, and then disperses to the outer baffle plate through the pipeline. After that, it flows vertically and radially to the inner baffle plate, and the packing is loaded between the inner baffle plate and the outer baffle plate, as shown in the figure below:

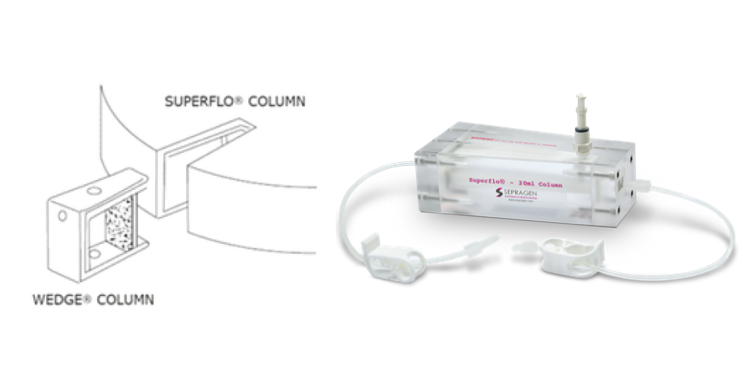

In order to keep the column height and linear velocity constant and achieve rigorous purification process amplification, Wedge column designed by combining the characteristics of radial and traditional axial columns was born. Easy linear scaling from lab-scale axial columns to large-scale radial columns.

The Wedge column is a scaled-down model of the larger radial column, similar to a cut cake, the larger radial column is a cake, and the Wedge column is a cut piece. As shown below:

Core Advantages of Radial Chromatography

Radial chromatography features the following:

- Faster flow rate, chromatography efficiency increased by more than 3 times, greatly reducing process development time

- The back pressure is lower, and higher fillers with particle sizes of 15μm or less that cannot be used due to pressure limitation in the current process can be used.

- Easy scale-up, better process scale-up consistency, smaller footprint after scale-up

- Better column efficiency and separation trends

- Prevent concentration-dependent precipitation and improve yield

- Easy to use, packing installation and removal without disassembly

Patented radial chromatography technology serves 40+FDA approved drugs and is market-proven with the core advantages of speed and efficiency, resulting in significant time and cost savings for customers in pilot and production.

Kelaiying Pharmaceutical Group (stock code: 002821.SZ/6821.HK) is a leading global CDMO company, providing high-quality R & D and production one-stop services for new drugs worldwide. To accelerate the launch of new drugs, extend the quality of life as its own responsibility, relying on continuous technological innovation, to provide one-stop CMC services for domestic and foreign pharmaceutical companies, biotechnology companies, accelerate the development and application of new drugs.

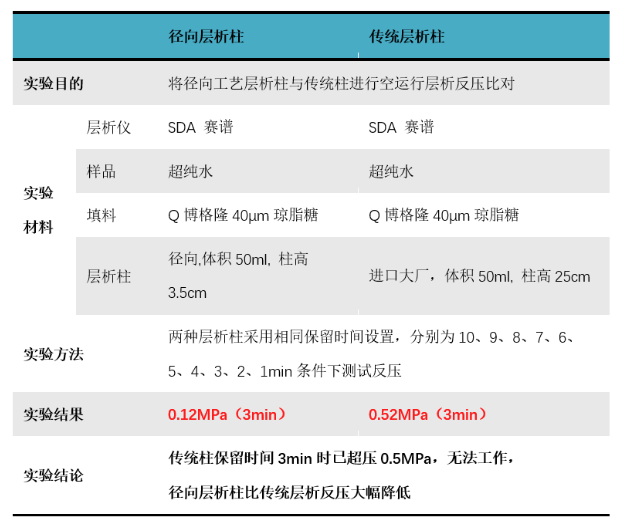

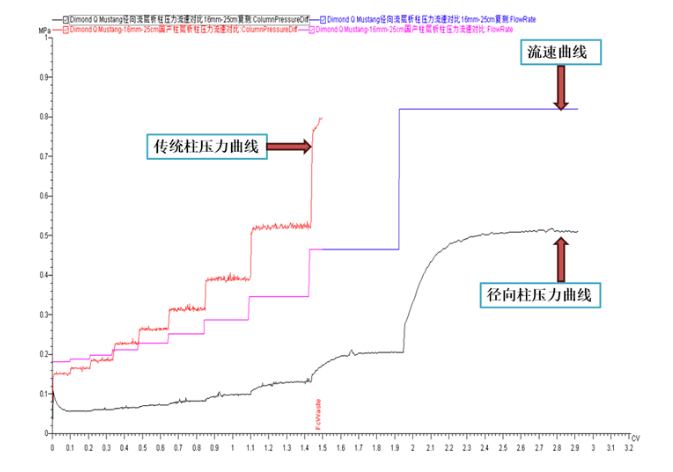

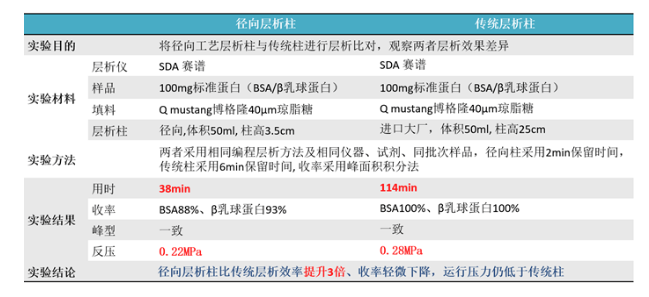

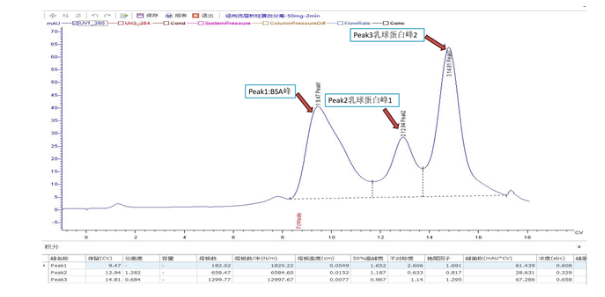

At present, the column height of chromatography column in process development and production of protein stock solution of biological products is usually higher than 10cm, and even as high as 30cm in some companies. Meanwhile, soft gel fillers such as agarose are commonly used as fillers. When chromatography is set with high linear flow rate and short retention time, high system back pressure will usually be generated, especially when the sample is loaded with full load or the fermentation supernatant is not good, which is easy to exceed the tolerance pressure of 0.3 Mpa, resulting in slow chromatography and low efficiency.

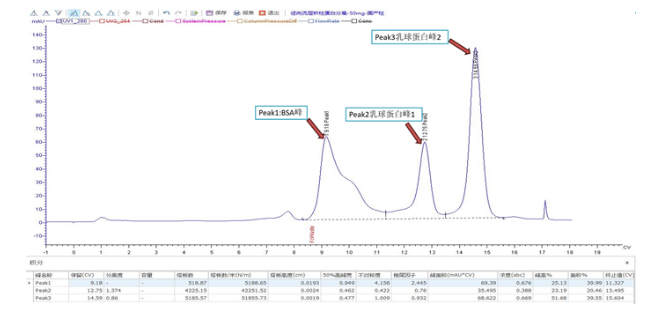

The patented design of radial chromatography column effectively avoids excessive system back pressure, which can greatly shorten retention time and improve chromatography efficiency. The performance of radial column is compared with traditional axial column.