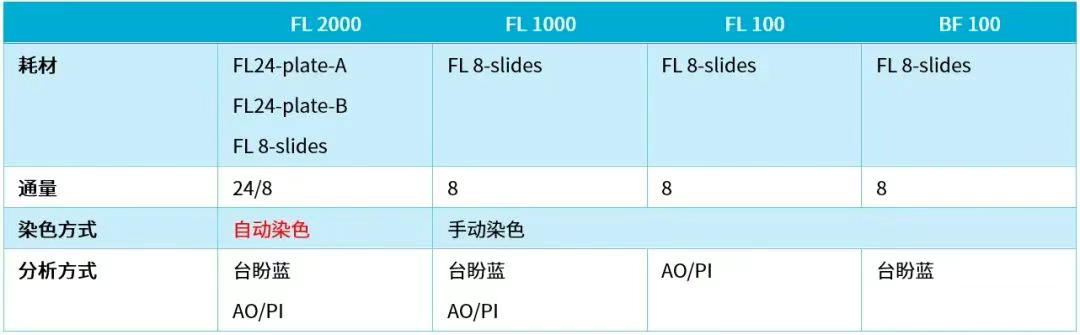

Bioprocess development is a critical aspect of biopharmaceutical production, encompassing media optimization, seed train preparation, and scale-up of bioreactor-based cell culture processes. Throughout these stages, researchers are often required to count hundreds of cell samples daily to assess cell status and viability—a task that is both labor-intensive and time-consuming. High-throughput automated cell counters can significantly streamline this workflow by rapidly providing key parameters such as cell concentration and viability, thereby accelerating experimental progress.

Market Pain Points

Pain Point 1:

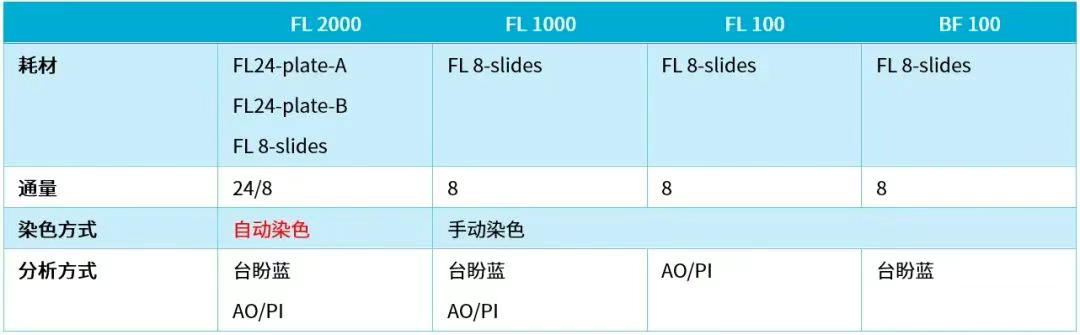

Currently, most cell counters on the market require the use of various types of consumables, generally falling into two categories. The first type uses slide-based consumable plates, typically with a throughput of fewer than 8 samples. This process requires manual sampling, dye mixing with trypan blue at a 1:1 ratio, and subsequent loading onto the slide. When processing large volumes of samples, a single lab technician may need to perform thousands of pipetting and mixing operations daily. The repetitive nature of these tasks significantly increases the risk of developing repetitive strain injuries, such as tenosynovitis.

Pain Point 2:

The second type of instrument captures images of cells as they flow continuously through a flow chamber. It relies on high-volume imaging for viability analysis and typically requires extended tubing and proprietary reagent kits (including dyes and cleaning solutions). This method consumes hundreds of microliters per sample and involves substantial time for each measurement. The long testing time and large sample volume requirements make it unsuitable for small-volume systems such as deep-well plates, shake flasks, or tubes used in early-stage cultures. Additionally, these instruments tend to be expensive, making them less accessible for routine use.

Pain Point 3:

Due to recent U.S. tariff policies, the cost of some imported cell counters and their corresponding consumables has continued to rise. The cost of counting a single sample can reach up to 10 RMB or more. For facilities processing 100–200 samples per day, this translates to monthly consumable costs of approximately 22,000–44,000 RMB, and an annual expenditure of 260,000–520,000 RMB. Such high operating costs pose a significant challenge for pharmaceutical companies striving to maintain cost-efficiency.

FL2000 – Free Your Hands and Eliminate the Counting Bottleneck!

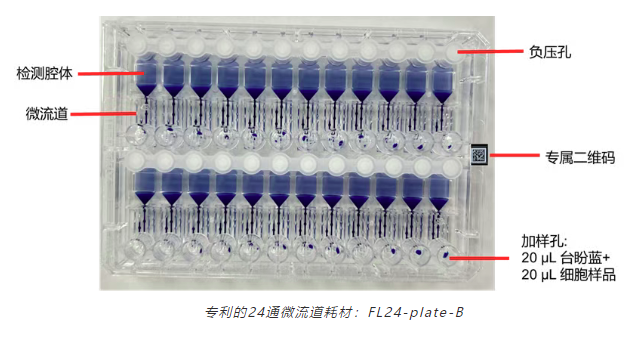

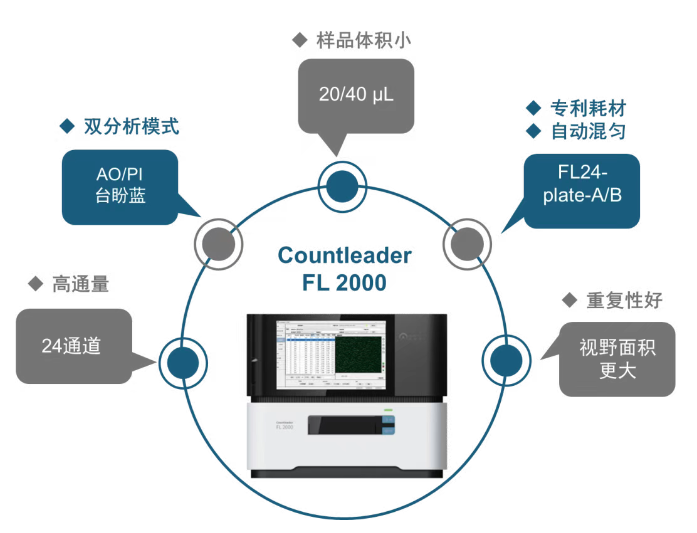

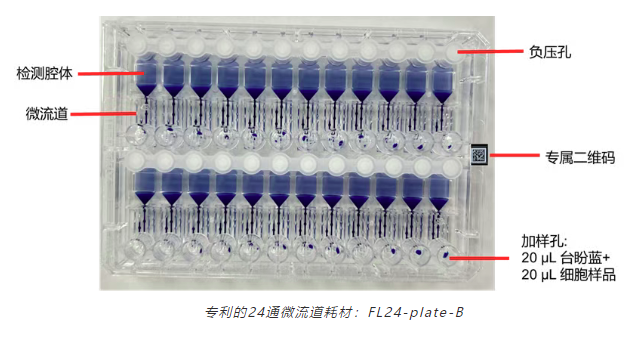

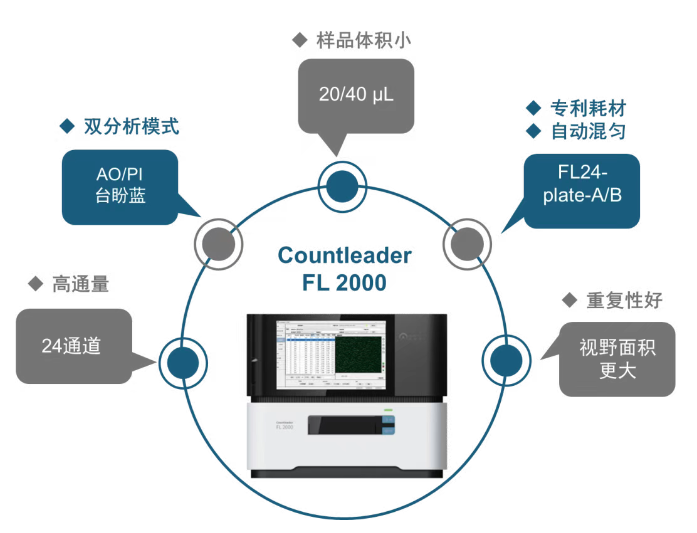

The Countleader FL 2000 is designed to address the challenges commonly encountered in process development, including high-throughput requirements, limited sample volumes, and restricted manpower. It utilizes a 24-channel microfluidic consumable—FL24-plate-B, optimized for Trypan Blue-based analysis. Each measurement requires only 20 μL of Trypan Blue and 20 μL of cell sample, enabling rapid and efficient cell viability assessment with minimal sample consumption.

- The sample and dye automatically flow into the microfluidic channels and enter the detection chamber, during which automatic mixing and staining are seamlessly performed. This fully integrated process ensures consistent and efficient preparation for accurate cell viability analysis.

- A dedicated QR code automatically records and calibrates the actual analysis volume.

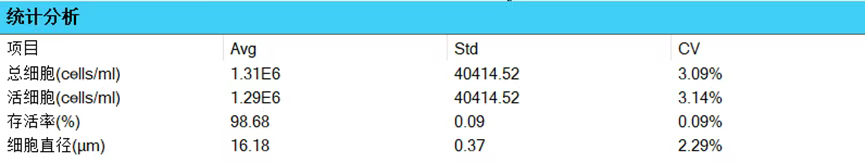

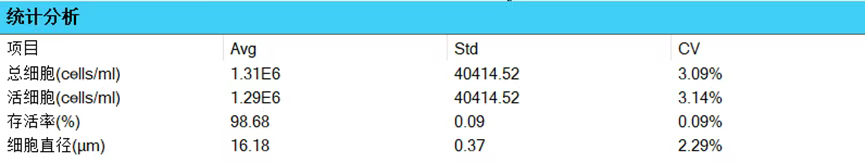

- High repeatability and stability, with a coefficient of variation (CV) < 5%.

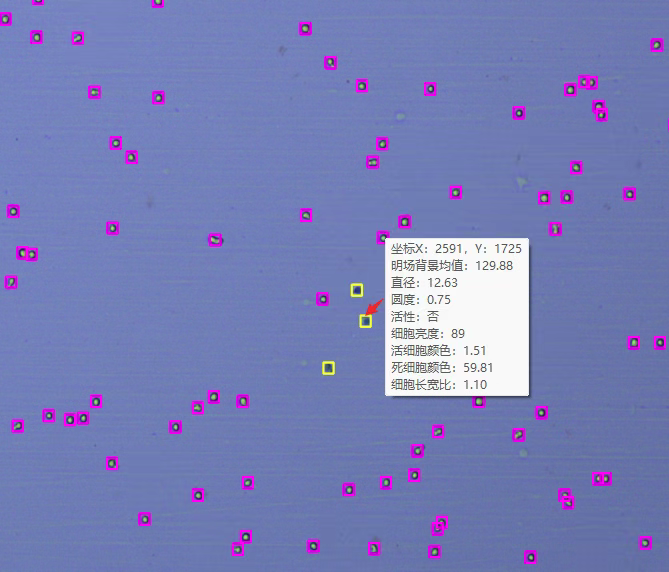

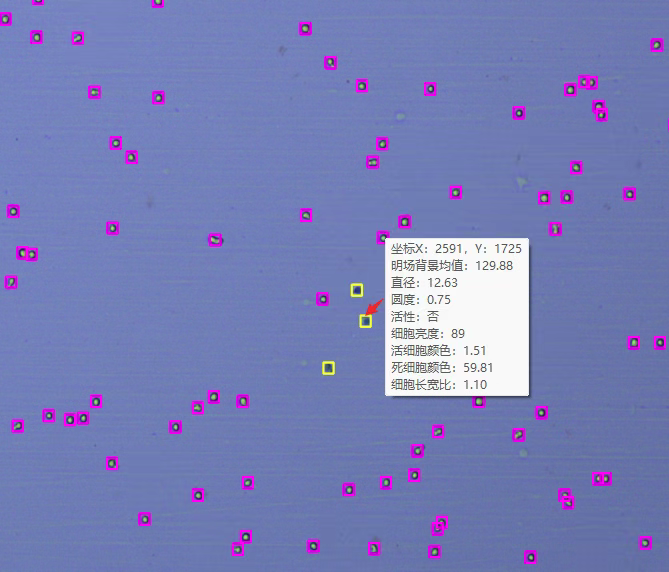

- Equipped with advanced software that provides comprehensive parameter visualization for each individual cell.

- The consumable cost per sample is just 25% of the cost of imported consumables, enabling companies to achieve significant cost savings and operational efficiency gains.

Result Reproducibility: CV < 5% within the optimal detection range.

Parameter Adjustment Interface

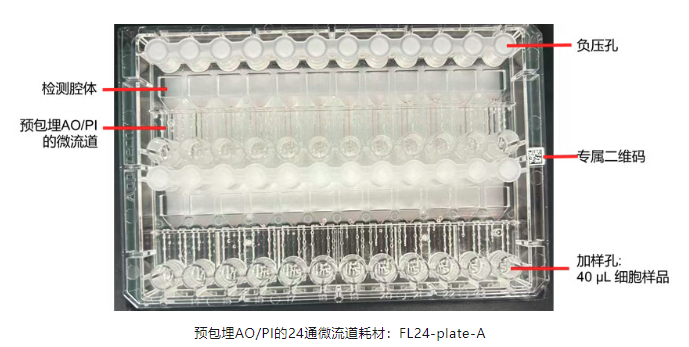

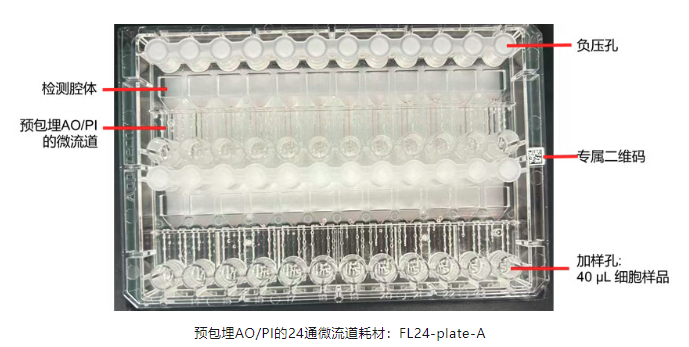

In the field of cell therapy, AO/PI dual-fluorescence staining is commonly used for cell counting. The Countleader FL2000 High-Throughput Cell Counter fully supports AO/PI fluorescence analysis and offers 24-channel consumables pre-loaded with AOPI dyes. Only 40 μL of cell sample is required per test.

- During analysis, the sample automatically flows through the microfluidic channels, dissolves the embedded dye, and enters the detection chamber—completing the mixing and staining process automatically.

- Each consumable features a dedicated QR code for automated recording and correction of the actual analysis volume, ensuring traceable and reliable data.

- The AO/PI fluorescent dyes selectively stain nuclear DNA, allowing the system to exclude debris and impurities, thus delivering highly accurate and reliable cell counts.

- With pre-embedded fluorescent plates, the FL2000 further reduces manual handling, minimizes variability, and enhances both usability and analytical precision.

The Countleader FL 2000 High-Throughput Cell Counter, when used with the FL24-plate microfluidic consumable, is perfectly suited for the high sample volume requirements in cell line development and process development, allowing for the rapid acquisition of precise and reliable cell counting results.

If you are currently facing challenges with high daily sample volumes, heavy counting tasks, and high consumable costs, we invite you to experience the FL2000 High-Throughput Cell Counter.