Company news

Company news

How to Accelerate ADC Drug Production Simply and Efficiently?

On the golden track of antibody-drug conjugates (ADCs), major pharmaceutical companies are joining the race, facing the ultimate challenge of balancing efficiency and quality. How can they navigate the complexities of production while mitigating cross-contamination risks, meeting flexible manufacturing demands, and managing steep cost curves?

As traditional stainless-steel equipment encounters the unique challenges of ADC manufacturing, single-use systems (SUS) are quietly reshaping industry practices.

-

Antibody Functionalization: Modifying the antibody to introduce the desired number of conjugation sites is a critical step in controlling the drug-to-antibody ratio (DAR) and ensuring ADC uniformity. Additionally, fragment formation needs to be carefully monitored.

-

Conjugation Process: Attaching the payload-linker to the antibody to synthesize the ADC, with a focus on controlling the DAR value and minimizing aggregate formation.

-

Purification Process: Removing process-related impurities (such as free small molecules and organic solvents) to ensure product safety.

Creating the optimal conjugation environment and controlling conjugation conditions are crucial aspects of the process. As large-scale production expands, the use of single-use mixing systems combined with single-use bags has made the conjugation process increasingly refined. This approach not only reduces contamination risks but also minimizes the time spent on routine cleaning and maintenance by operators, ultimately streamlining production in a simple and efficient manner.

Due to the complexity of ADC processes and components, stringent requirements are placed on production technology, equipment, and consumables. To address the critical aspects of conjugation, Applitech offers a variety of mixing solutions and provides professional technical support with comprehensive selection recommendations.

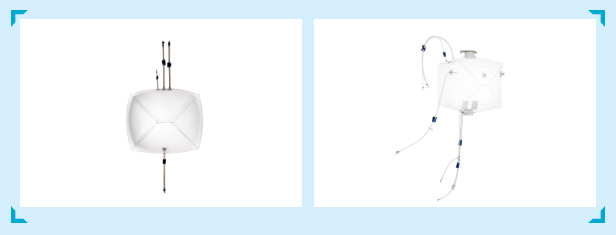

The AbioMixer® tabletop mixing system and bottom-driven magnetic mixing system from Applitech integrate multiple functions, including stirring, weighing, printing, pH measurement, conductivity monitoring, and temperature control. These systems are designed for ADC reactor conjugation processes and offer the following advantages:

- User-Friendly Operation: The equipment is designed for simple and intuitive use, making it easy for operators to install, operate, and dismantle, thereby reducing operational errors and improving production efficiency. Additionally, it offers excellent visibility, allowing operators to monitor the mixing process in real time.

- Scalability: As research progresses and production scales up, the equipment and consumables can be easily integrated or upgraded to accommodate different stages of production needs.

- Online Monitoring: Equipped with inline monitoring devices such as pH sensors, temperature sensors, and conductivity sensors, enabling real-time tracking of critical parameters during the mixing and storage process to ensure compliance with quality standards.

- Uniform Mixing: The well-designed stirring or mixing system ensures that antibodies, toxins, linkers, and other components are thoroughly and evenly mixed in the storage and mixing equipment. This guarantees the efficiency and uniformity of the drug conjugation, enhancing the conjugation reaction and ultimately improving product quality.

Applitech AbioMixer Desktop Mixing System and Magnetic Mixing System

The Applitech Haimore Series single-use storage bags comprehensively meet the precise control requirements for parameters in the conjugation process. They support a range of volume needs, making them flexible enough to adapt to different stages of research and scaled-up production. The bags also offer the following advantages:

-

Superior Material: Made from biocompatible materials, the bags avoid interactions with the active ingredients in ADC drugs, ensuring the quality and activity of the drug are not affected.

Chemical Compatibility: Designed to withstand various chemical reagents and solvents used in the ADC drug production process, the bags are resistant to leaching, adsorption, or chemical reactions, ensuring the stability and purity of the drug components.

Sterile Design: Using irradiation sterilization, the bags ensure a sterile state during storage and mixing, preventing microbial contamination and maintaining a sterile environment for ADC drug production.

Cost Reduction and Efficiency Improvement: Single-use storage bags reduce procurement and usage costs while increasing the lifespan and cost-effectiveness of equipment, ultimately improving production efficiency.

-

Quality Traceability: The single-use storage bags are traceable, with production batch numbers, usage records, and other relevant information fully documented, enabling tracing and analysis in case of quality issues.

Applitech Haimore Single-Use Storage Bags

Applitech is committed to serving the biopharmaceutical industry, helping every client enhance production efficiency. By optimizing equipment design and operational processes, Aibeta reduces auxiliary time spent on tasks such as equipment cleaning and preparation, ultimately streamlining the ADC drug development and production cycles in a simple and efficient manner.